In the midst of the global Covid-19 pandemic outbreak, most organizations throughout the world are focused on finding immediate solutions for containing the spread and curing the virus. As a worldwide manufacturer and supplier of personal protection equipment (PPE), the Supermax Corp. team is working tirelessly in that direction to make sure that all healthcare workers and other front liners get the supplies they need to achieve their heroic work.

Emergency responses aside, this crisis has also been a wake-up call for many about the need for global safety protocols updates and alignment, information transparency, as well as social and environmental sustainability. Long-term commitments from all organizations around the world will be equally as important as short-term solutions to ensure the sustainability of our societies and economies.

For those reasons, Aurelia Gloves Canada has undertaken several green transition initiatives in the past year. And one of these initiatives has come to completion: the Carbon Neutral Certification. We are very proud to achieve this significant milestone, as we evolve in an industry that has historically been emitting high volumes of CO2 and other wastes. This is one of the first tangible results from our constant efforts to make a difference and challenge the status quo on sustainability issues in our industry, with many more good news to come. Here is what this certification means and why it matters.

What are carbon neutrality and the Carbon Neutral Certification?

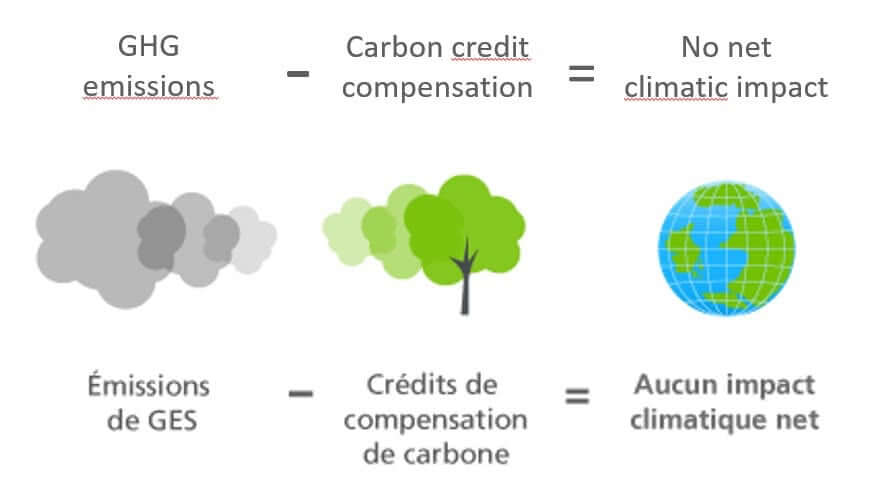

![]() Carbon neutrality, or having a net zero carbon footprint, refers to achieving net zero carbon dioxide emissions by balancing carbon emissions with carbon removal (often through carbon offsetting) or simply eliminating carbon emissions altogether. It is used in the context of carbon dioxide-releasing processes associated with transportation, energy production, agriculture, and industrial processes. Carbon-neutral status can be achieved in two ways: (1) reducing carbon emissions through changing energy sources and industry processes, and/or (2) balancing carbon dioxide emissions with carbon removal beyond natural processes, often through carbon offsetting, or the process of removing or sequestering carbon dioxide from the atmosphere to make up for emissions elsewhere[1].

Carbon neutrality, or having a net zero carbon footprint, refers to achieving net zero carbon dioxide emissions by balancing carbon emissions with carbon removal (often through carbon offsetting) or simply eliminating carbon emissions altogether. It is used in the context of carbon dioxide-releasing processes associated with transportation, energy production, agriculture, and industrial processes. Carbon-neutral status can be achieved in two ways: (1) reducing carbon emissions through changing energy sources and industry processes, and/or (2) balancing carbon dioxide emissions with carbon removal beyond natural processes, often through carbon offsetting, or the process of removing or sequestering carbon dioxide from the atmosphere to make up for emissions elsewhere[1].

Carbon neutrality is achieved by calculating a carbon footprint and reducing it to zero through a combination of efficiency measures in-house and supporting external emission reduction projects.

The Carbon Neutral Protocol gives businesses a rigorous and transparent framework to deliver carbon neutrality for their business, products and/or activities[2].

Why did we commit to become carbon neutral, and why does it matter?

Due to intensive greenhouse gas emissions throughout the 20th and 21st century, we have reached a level of CO2 concentration in the atmosphere that is twice higher than any levels measured in the history of our planet, with no signs of slowing down. At the current pace, the aftermath of global warming become visible and measurable during our own human lifetime, and we are at risk to face multiple other global crisis that can have a un unprecedented impact on the survival of humanity. In order to simply achieve a 1.5 C temperature rise by 2050, we must reduce global CO2 emissions by over 80%.

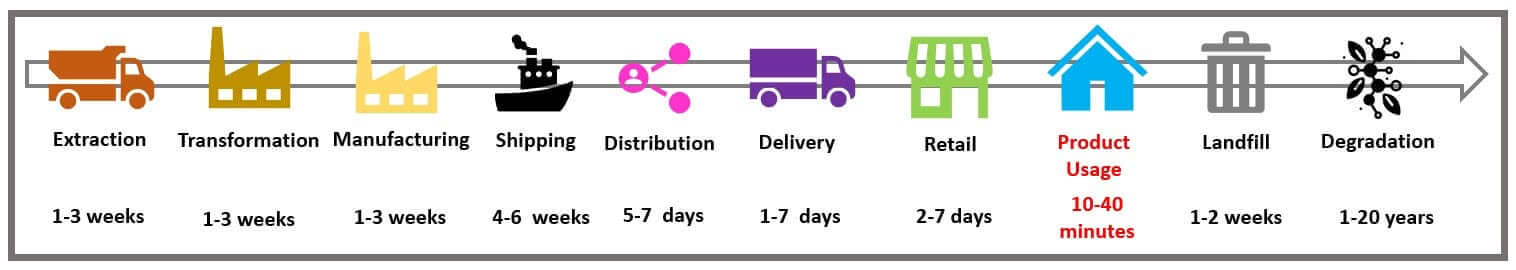

Compared to other sectors, the PPE industry has a significantly long, complex, and traditional supply chain. The raw materials we use (such as nitrile, latex, vinyl, polypropylene, cotton, paper) often require intensive extraction and transformation processes in order to be used for manufacturing. Because of the limited geographical availability of these materials, manufacturing is for the most part concentrated in a handful of locations in the world, and shipping has to be done over long distances to reach national distribution networks. Once arrived, these products go from hand to hand to finally get to the end user, who will make use of the products for 10 to 40 minutes duration before discarding them. From there, the waste management pathway is the longest of all product lifecycle stages. And because most materials used to make PPE products have historically been driven by intensive processing and cost optimization with little concern to environmental sustainability, their complete degradation can take up to 20 years.

As a company, Supermax Healthcare Canada has committed to address these critical industry issues and reduce its environmental impact by comprehensively rethinking the product lifecycle and product components we use, as well as optimizing the waste management path for our products.

The Carbon Neutral Certification is the result of Aurelia’s commitment to manage and offset all carbon emissions related to the part of the product lifecycle we directly manage. With the help of LCL environment, a Canadian certified organization for assessing companies’ carbon dioxide emissions, we could measure our total CO2 emissions at 110 tons for 2019, and we have sponsored the plantation of 785 trees to fully offset these annual emissions. We will assess our emissions and plant trees to offset them every year from now on. This is a first achievement in improving the product lifecycle, and it won’t stop here. We are currently working on additional initiatives with our business partners to reduce and offset all CO2 emissions along the entire supply chain for our products.

We have also achieved numerous Eco Conception projects, transforming the way PPE products are made and the materials that are used. All our disposable paper & plastic products are recyclable, and we are currently developing biodegradable and compostable alternatives to these products.

We have also just released the Renew nitrile glove which has a 20% biodegradation rate within the first year of landfill disposal compared to the 2.5% industry average rate for nitrile gloves. With a half-life that is about 10 times shorter than other disposable gloves on the market, this improvement is a key milestone in minimizing the environmental impacts of PPE wastes. Again, the effort does not stop here, and our R&D team is currently working on numerous similar projects for products such as gloves, face masks, and more.

So, what’s next?

Within the next year, there are several milestones that we are working to hit such as:

- Becoming a one-stop-shop for all eco-friendly PPE products used in various sectors such as the healthcare, dental, sanitary, and beauty industries.

- Launching a new kind of customer loyalty program based on eco-friendly products tonnage consumption. Upon shifting from traditional PPE products to eco-friendly products, customers will be rewarded with gratuity and discounts for future eco-friendly supplies purchases based on the tonnage of waste our customers put on a biodegradation, compost, or recycling path.

- Creating and sharing informational and educational content for sustainable and responsible usage of PPE. Through web content and in-person training, we want to sensitize all PPE users about the environmental issues related to these product as well as spread a maximum awareness and knowledge about sustainable PPE usage.

- Achieving all the social, environmental, and organizational requirements to become a B-Corp. It is critical for us to channel all our sustainability initiative towards a unilateral and coherent direction. And the pathway to become a B-Corp will allow us to cover all the necessary ground about our products, our processes, our network and our people to become a comprehensively sustainable organization.

To stay up to date with our latest initiatives and releases, subscribe to our company’s newsletter. And if you would like to explore collaboration opportunities for this type of sustainable innovation project, feel free to reach out to our team!